Quality Control

Brown Boxes features world-class Quality Control instruments for monitoring & maintaining quality at every stage – Raw Material, Printing, Lamination, Corrugation, down to the finished product. We have set benchmarks for excellence in Designing, Printing & Packaging. Quality is an attitude. The machines, the process, the procedures, all follow this attitude. And this attitude is more inborn, than statutory. You can buy all the equipment in the world, but without the obsession inside, they will all stop short of the final mile to perfect quality.

What is more, in keeping with its policy of transparent enterprising?

COMPRESSION STRENGTH TESTER

The compression strength test is used to measure the force which the corrugated box can withstand before crushing. By doing a compression strength test we can determine the stacking strength of the corrugated box. This test is essential for the customer as it measures the compressive resistance, deformation, and stacking capability of the corrugated box.

BURSTING STRENGTH TESTER

Bursting Strength Test(BST) is one of the reliable tests of the corrugated boxes to realise the strength and performance of paperboards and corrugated boards and boxes. BST is ideal for testing corrugated boxes to determine their quality, strength and performance. BST is scientifically calibrated for reliability and is easy to operate and user-friendly.

BOARD & PAPER MOISTURE TESTER

Board and paper Moisture meter with LCD and rugged housing so that the pins on the end of the instrument can be pressed into corrugated parts to measure the moisture content. However, the instrument is subject to be calibrated for that particular material or a factor can be arrived at wherein the factor is multiplied to achieve the exact moisture content.

ELECTRONIC GSM TESTER

Electronic GSM tester measures and indicates the substance of paper in terms of grams per square meter. The tester displays the grams per square meter of samples cut selected to size on a digital indicator. This GSM value can be used in Bursting Strength Tester to get the burst factor of any paper or corrugated box which is an important factor in the packaging industry.

BOX WEIGHING MACHINE

Box weighing machine measures the exact weight of the ready unit of the corrugated box to give an idea about the weight of the box.

COBB TESTER

The Cobb tester is used to determine the amount of water absorbed into the kraft paper by a sized(non-bibulous) paper, paperboard, and corrugated fibreboard paper or paperboard sample in a set period, usually 60 or 180 seconds.

Hi-Tech Equipments & Advanced Technology

DIE CUTTING, CREASING & EMBOSSING PLATEN

Size: 44”x56”

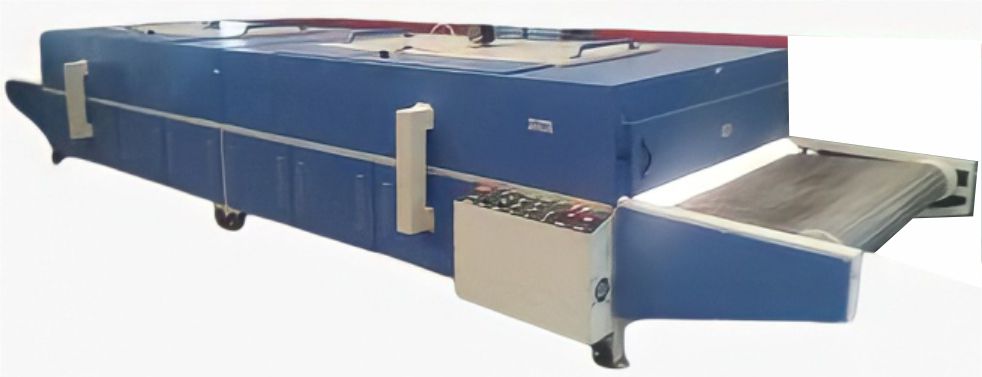

CORRUGATED BOX DRYER

AUTO FEEDER 2 COLOR PRINTING & SLOTTING MACHINE

Size: 86”

LAMINATION MACHINE

Size: 36”

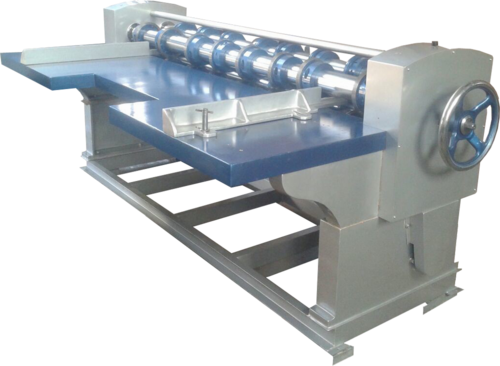

THIN BLADE CUTTING & CREASING MACHINE

Size: 72”/84”

SEMI-AUTOMATIC FOLDER GLUER MACHINE

Size: 86”

CHAIN FEEDING ROTARY DIE CUTTING MACHINE

Size: 86”

FLEXO BOARD PRINTING MACHINE

Size: 52”x86”

4 BAR ROTARY CUTTING & CREASING MACHINE

Size: 72”/84”

SHEET PASTING MACHINE

Size: 86”

OVERHUNG ECCENTRIC SLOTTER

Size: 72”/84”

BOX STITCHER

Size: 48”

HIGH-SPEED CORRUGATION MACHINE

Size: 52”(B Flute)

DOUBLE PROFILE HIGH-SPEED CORRUGATION MACHINE

Size: 42”(B+C Flute & B+E Flute)

ROTARY REEL TO SHEET CUTTER

Size: 52”